Spark Plasma Sintering (SPS) Setup (2000 A Capacity); Spart Plasma Extrusion (SPE) Setup (2000 A Capacity)

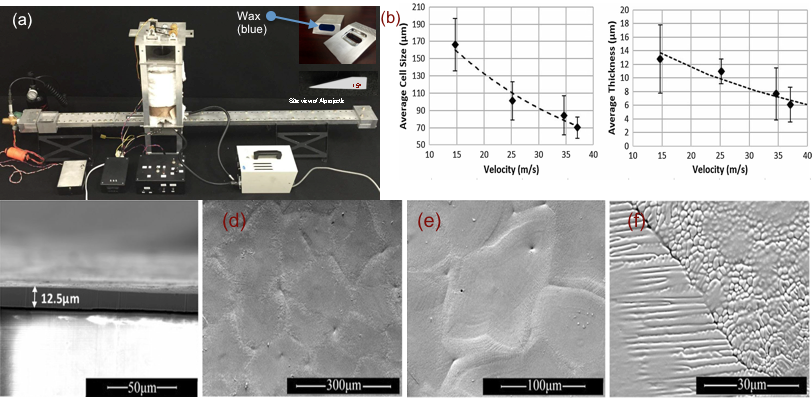

Ballastic Processing Setup for Thick Film Manufacturing

pH Meter

AMPL, Dept of Mechanical Engineering, 5500 Campanile Drive, San Diego

CA 92182-1323

kmorsi@sdsu.edu